Do More, Faster, Better and cheaper – with Govro

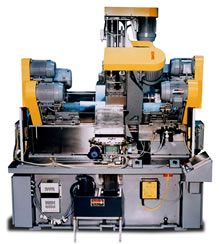

Govro-Nelson offers a complete line of GOVRO™ drilling/tapping units and high production machines. For over 50 years, customers have chosen Govro for machine solutions that increase profit margins by decreasing processing costs. Typical products appear in the following pages.

Diverse customer applications and product configurations dictate flexibility in Govro product offerings. For example, budget restrictions, product specifications and labor requirements are all taken into account when Govro quotes a machine.

The Govro-Nelson Company has a long history of solving tough manufacturing problems with innovative machine designs. From single station, single operation machining units to multi-station indexing machines accommodating up to 19 machining units, Govro has been successful in combining high volume manufacturing with low cost operation and exceptional quality. Govro has been serving the drilling and tapping needs of the metalworking industry for over five decades and enjoys an unmatched reputation for quality and service.

Send Govro engineers your part specifications for a machine design to improve your manufacturing.

The Importance of Concentric Construction

The concentric construction of Govro machining units combines air thrust, hydraulic control and positive stop—all on the spindle centerline. Concentric design minimizes quill deflection, affords longer life for the unit, tools and bushings, while assuring uniformly accurate parts. The closed circuit hydraulic system, always under pressure, prevents chips and coolant from entering the system and automatically adjusts for oil seepage to lubricate seals for longer life. The hydraulic feed control has no axial backlash, minimizing the ‘drill drive’ at breakthrough—which may occur with a mechanical system.